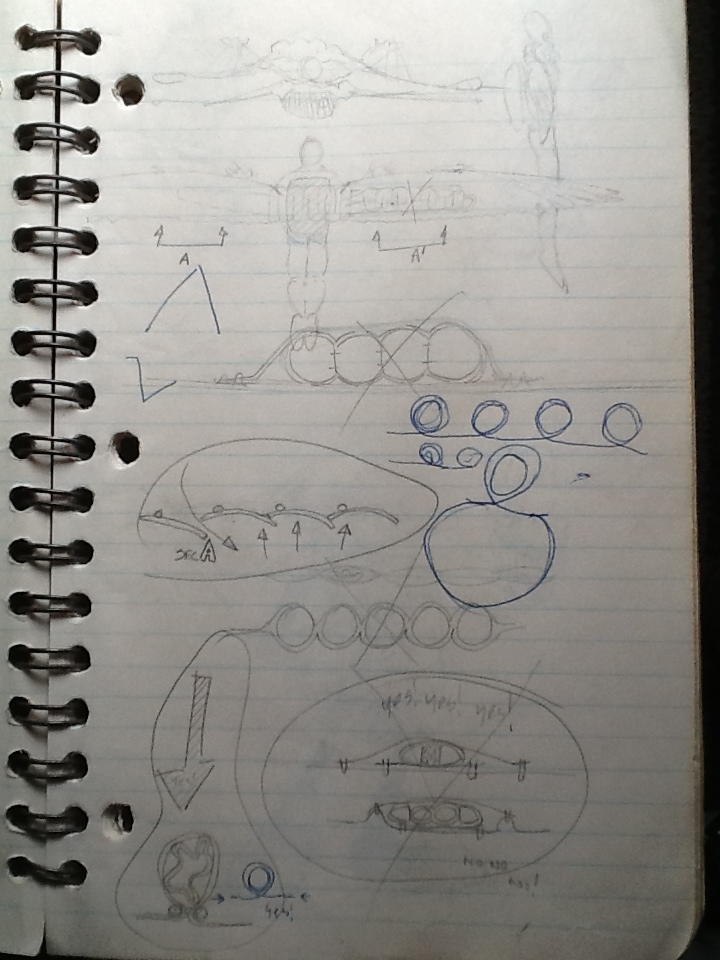

This one I'm calling Swimmer Wing, meant to be one of two sets of wings that counter-rotate with respect to each other, in a dragonfly format, for inertial balance.

Wavy wing, 3d morphable airfoil

This one looks cool, if I do say so. The point of it being "corrugated" is to allow all of the motions to merely change the local waviness of a rigid skin in response to combinations of curvature.

Early solidworks morphing wing

I call this an early model because I'm just learning how to make solidworks animate this type of shape change. It's a notional model still, and the only thing you should take from this animation is that it must be made of rubber to do what the central spar is asking of it.

My current thinking is to try for a single curved spar with simple bearings at the ribs. Without a sliding interface between spar and rib, the airfoil is going to swing forward and back as it flaps. Ill discuss ways to cope with that soon. I'm letting go for the moment the concept of storing energy in the spar, and assuming for now that the spar is going to be far too stiff for that, so I need to learn how to deal with fore and aft flapping that goes with the kind we want. (That is, explore it for a bit before reverting to the twin opposing spars I animated earlier.). Having a single spar and less mechanism is worth seeing if it's possible to cope with its weirdness.

All this leads to the first major riddle to this: how to make a rigid skin adapt to complex curvatures. Not njust flap and twist now, but add reaching fore and aft. One effort I found on the net talked to 2d stretchy fabrics, but really, in order to aim high, the goal needs to start with a laminar flow airfoil, and compromise as necessary, which is likely.

Laminar flow will depend on surface smoothness and a viable airfoil no matter where you take a cross section of the wing.

That last qualifier will make sense on the next post.

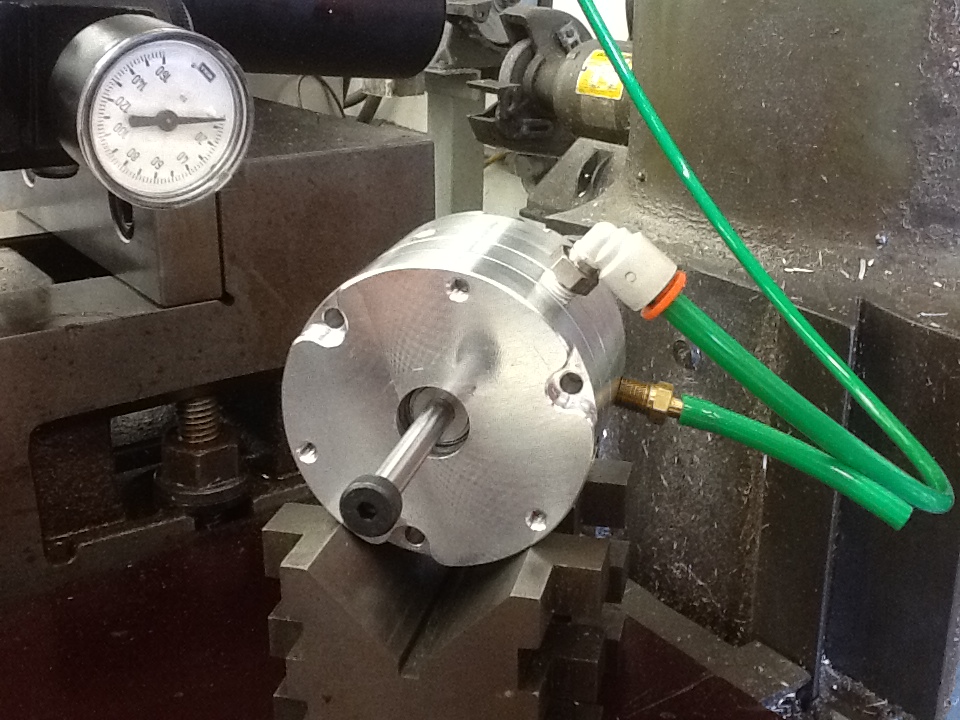

Airmotor Run 2 Video

...the video didn't attach properly, so here it is.

Air Motor Run 2

Air Motor Prototype Runs Great!

Mannequin gets springy

Sent from my iPad

Mocking up Exoskeletons

Sent from my iPad

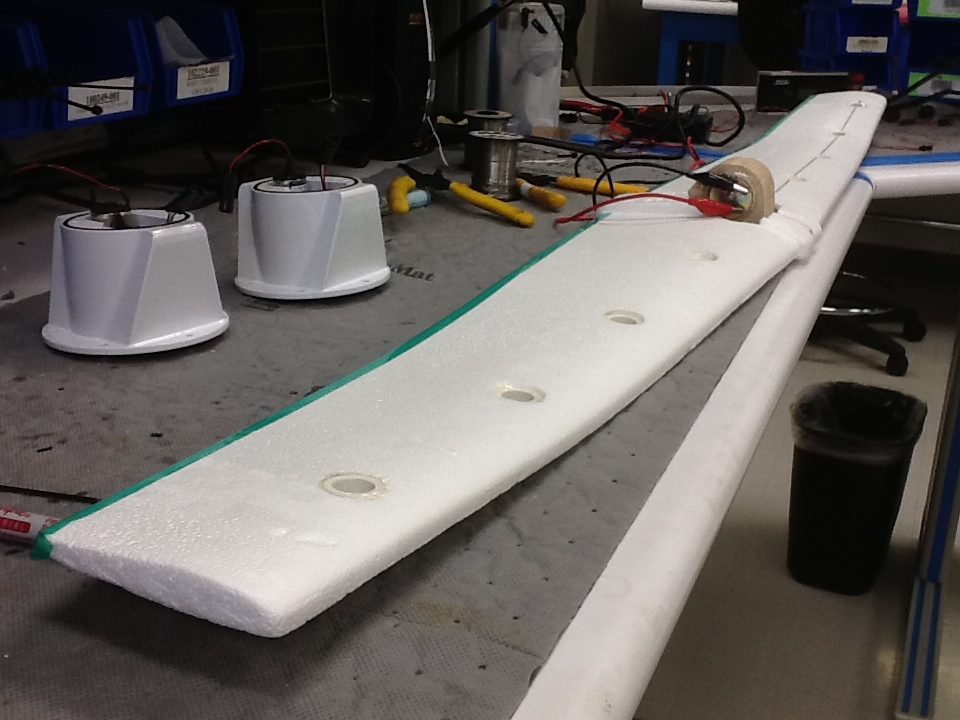

Curved spar wing warping demo

>

>

Some Whys of the Manithopter

A closer up view of the counter-rotating spars doing a flapping action

This is a little better view of the previous flapping animation. Still just wrapping my mind around using the curved torsion spars. Coming up are posts showing a composite lattice wing build, and some bits on the pilot's exoskeleton, which we will be molding directly on our pilot Matt's body. Hope we can get him out of it. ha

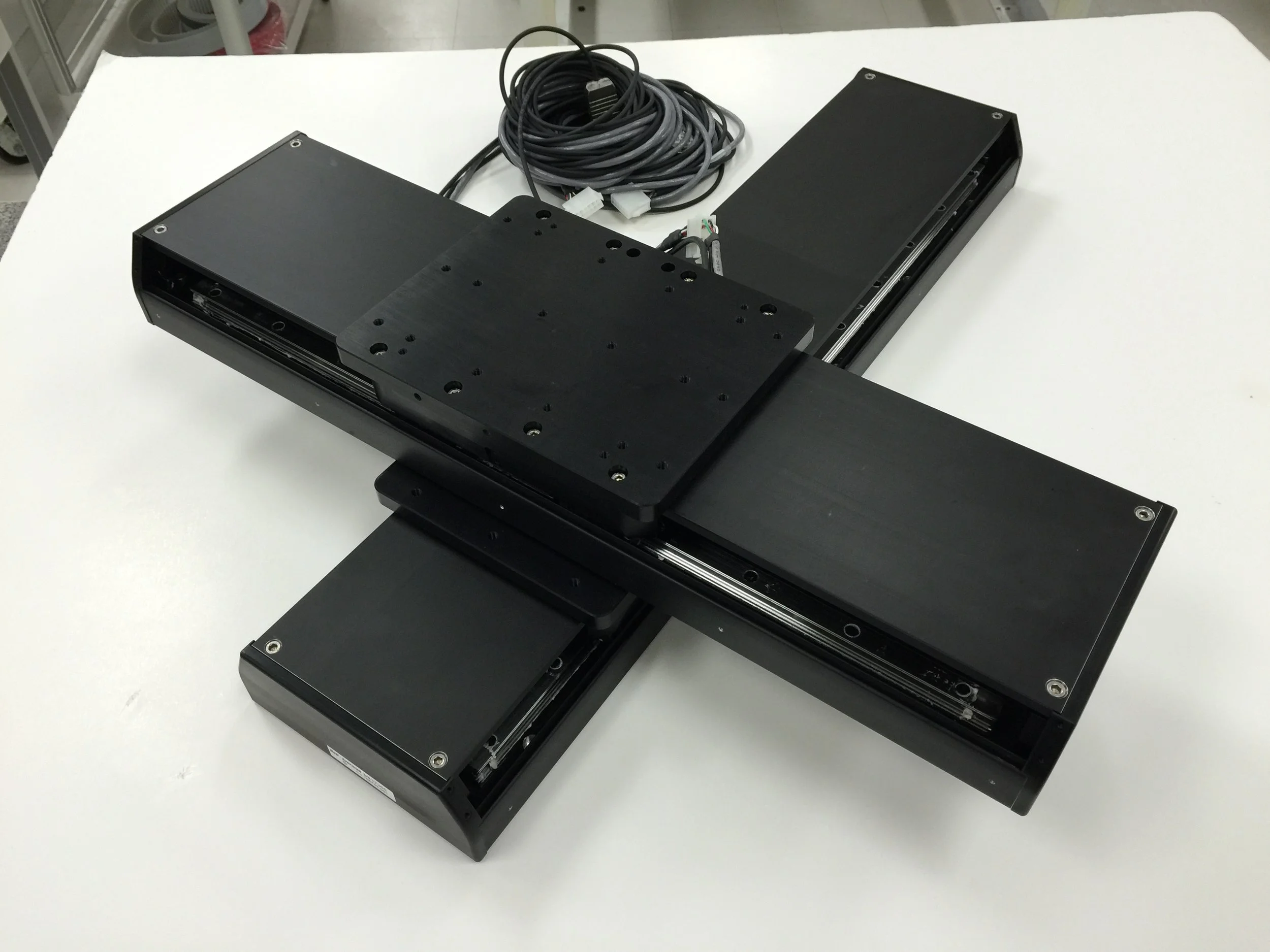

Animation of counter-rotating curved spars and centerline lincage

This animation illustrates one way of using balanced counter-rotating curved spars. I've added a notional lincage to control a spar extension that is on the mechanism centerline. Ultimately, I'm going for something simpler. Animation and design work done in Solidworks.

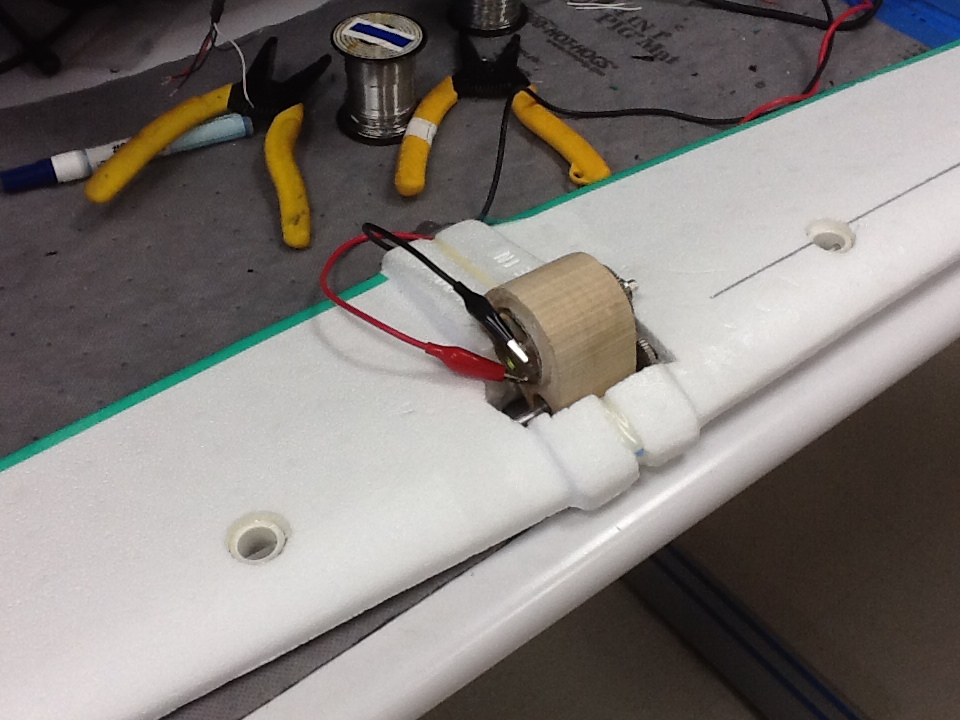

Quicky driven morphing spar

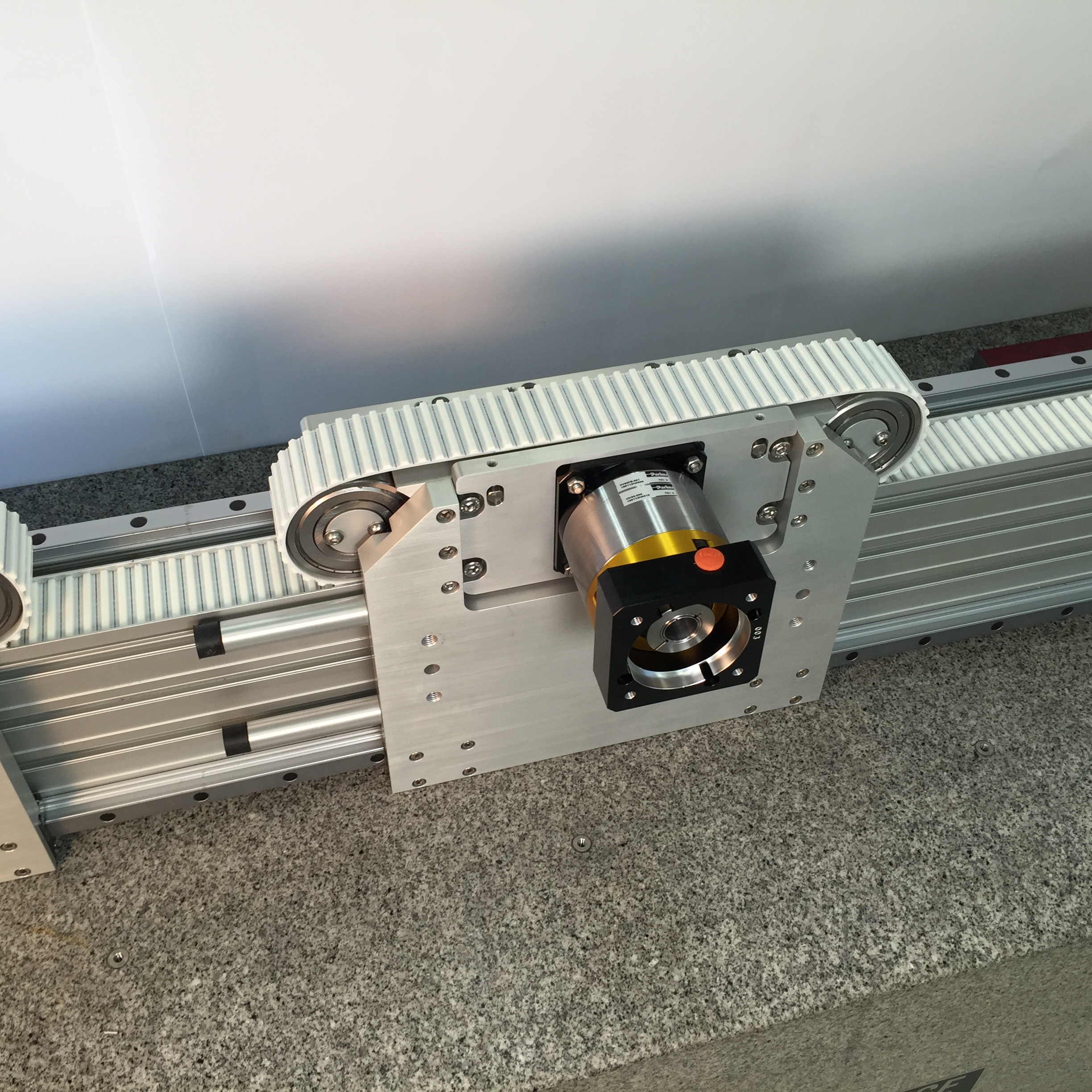

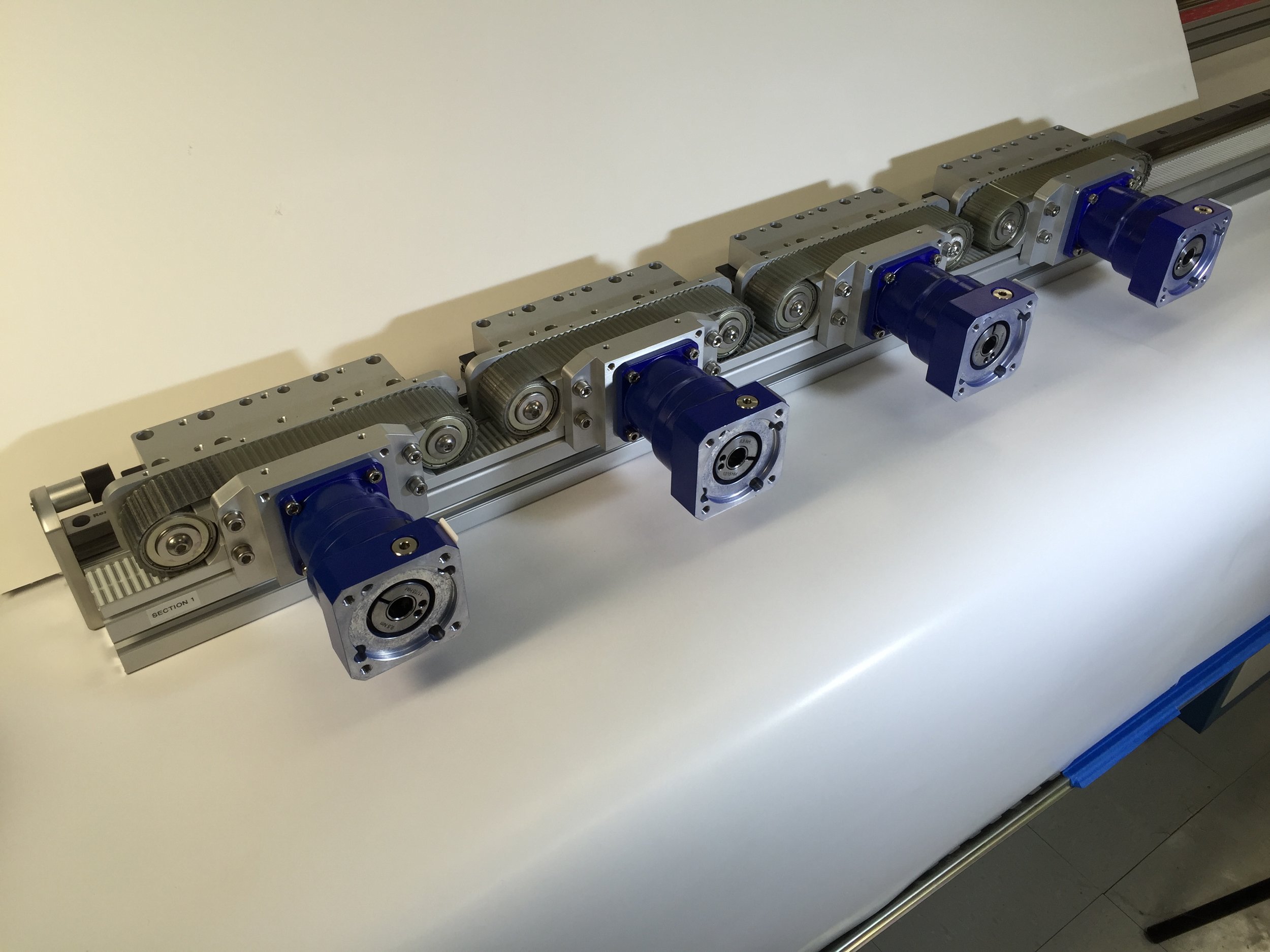

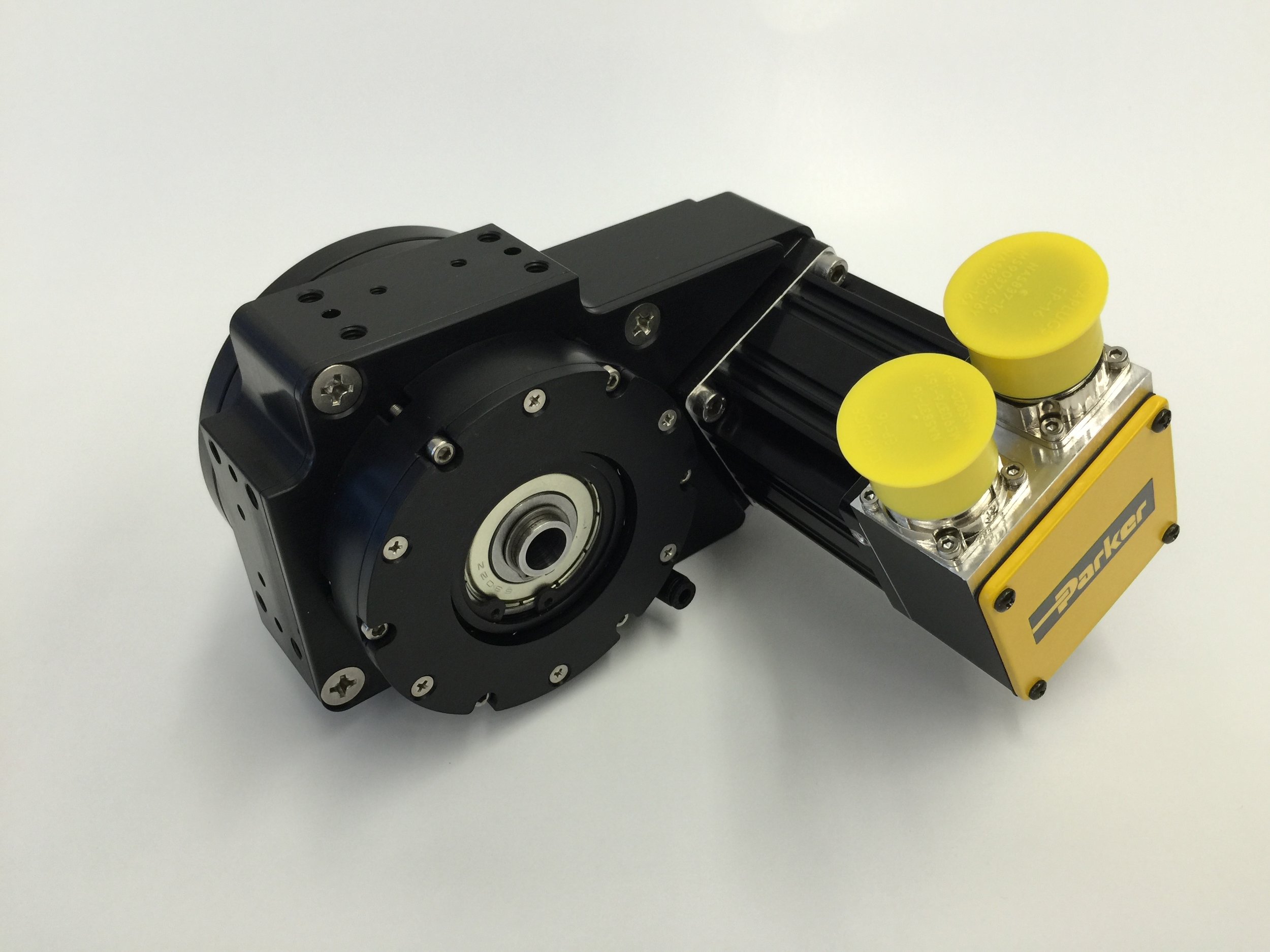

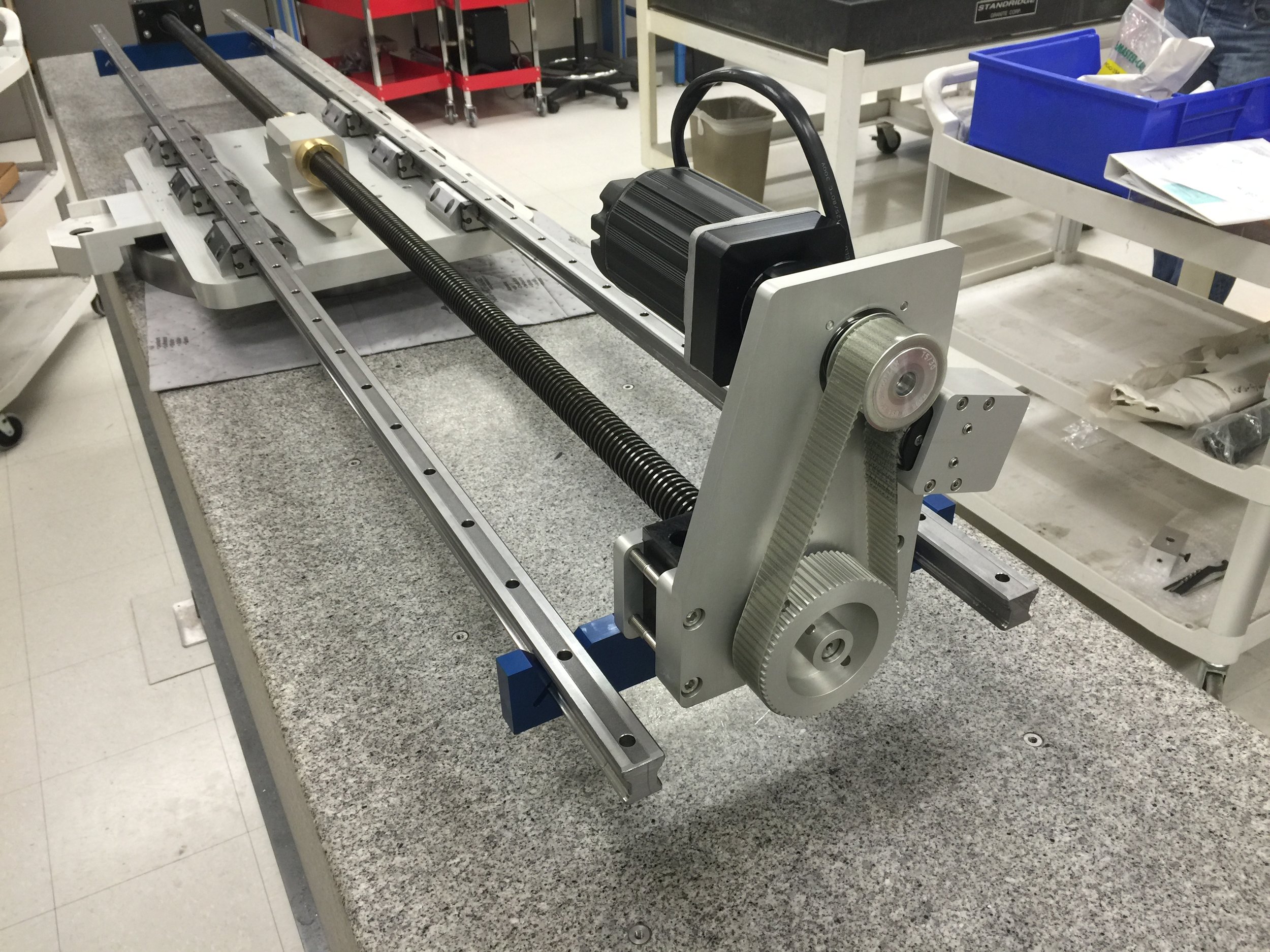

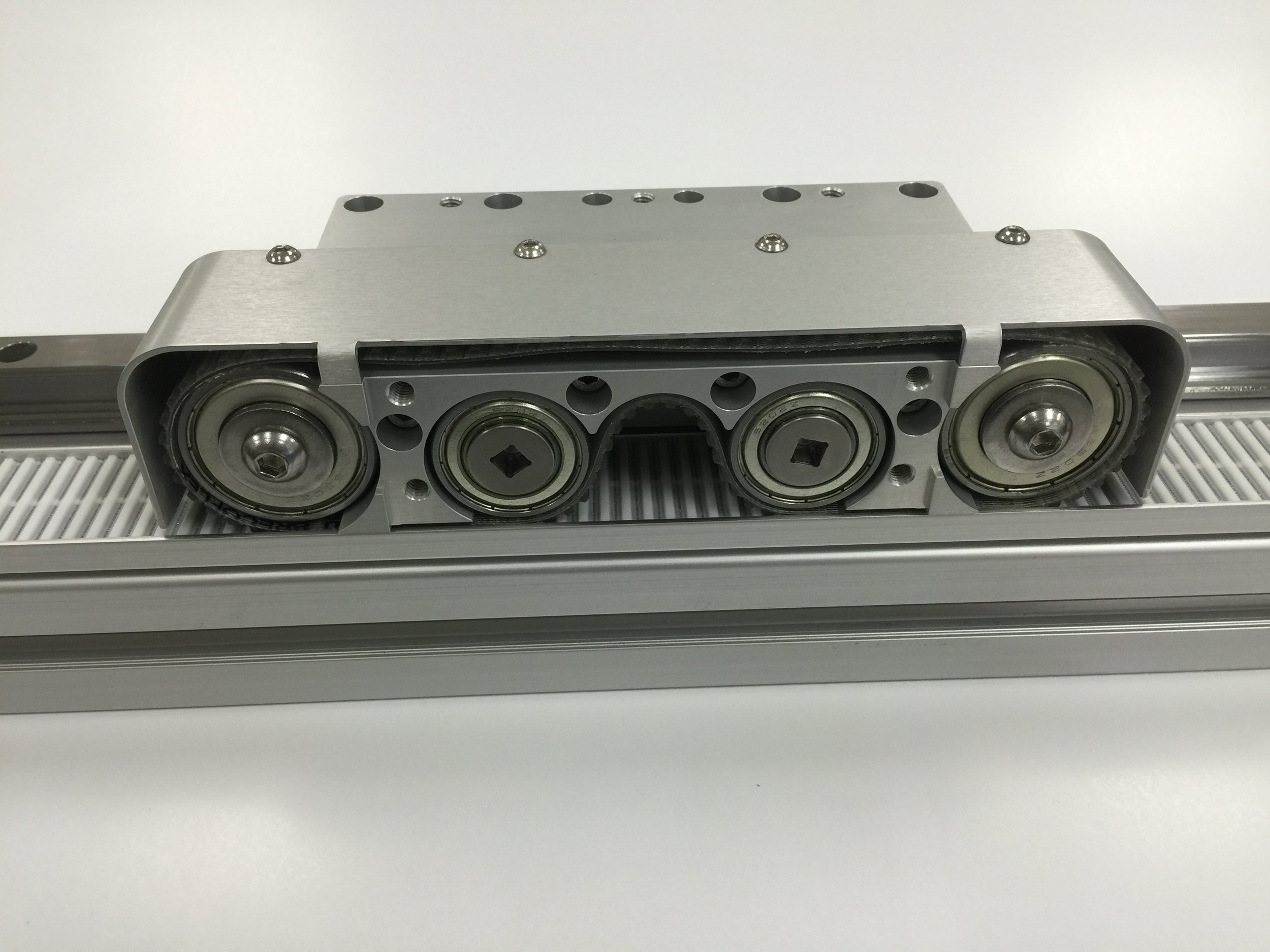

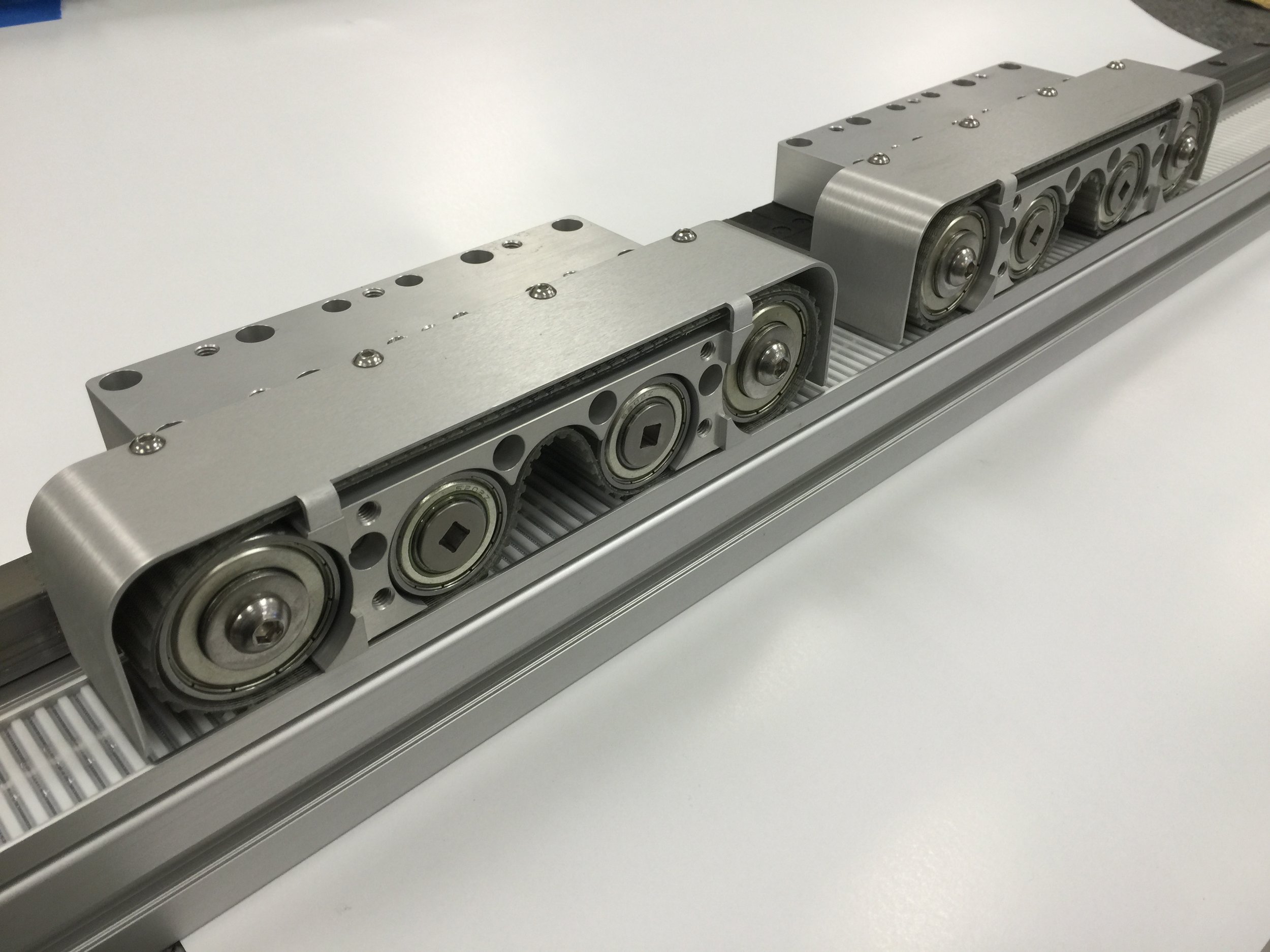

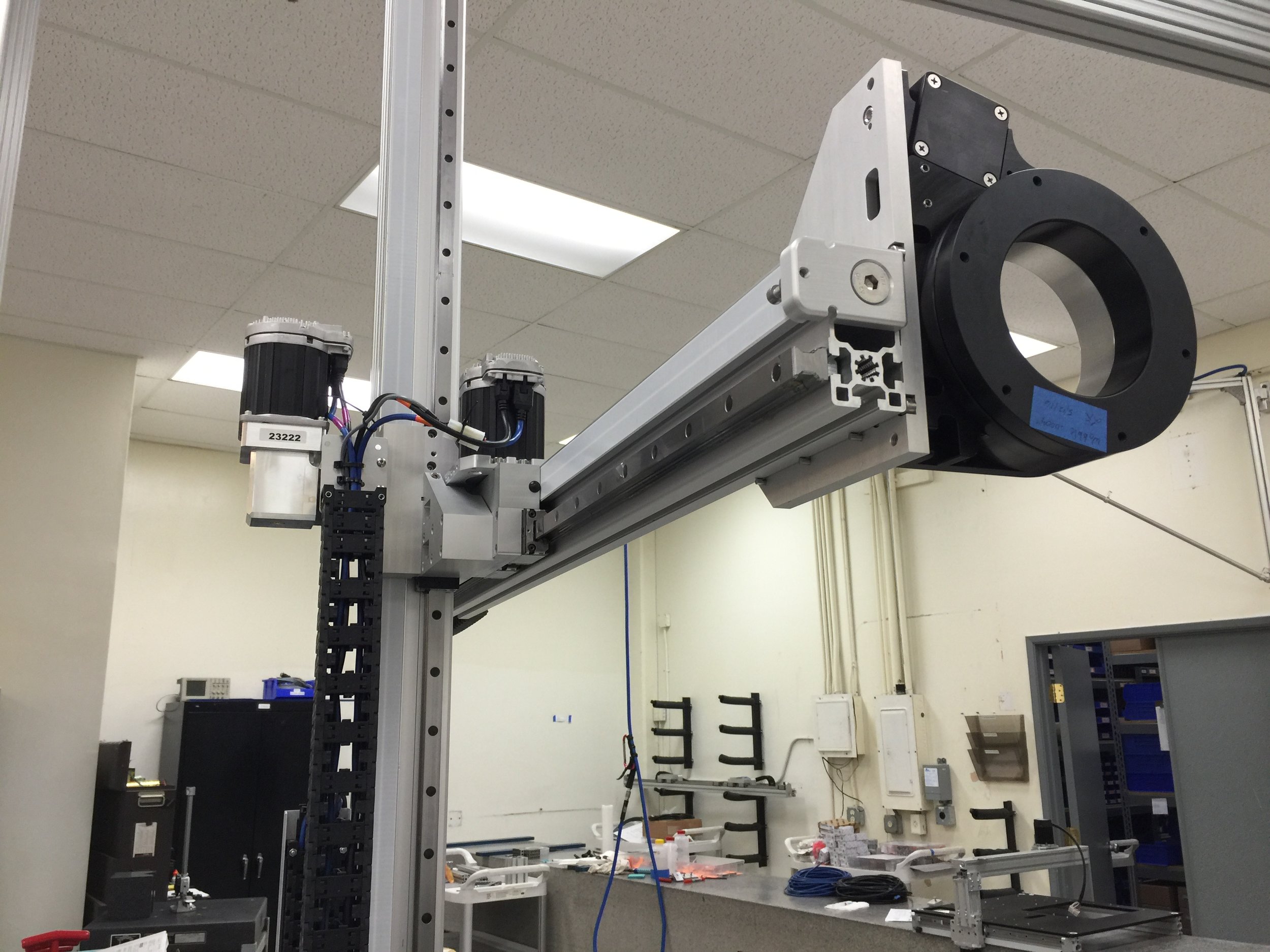

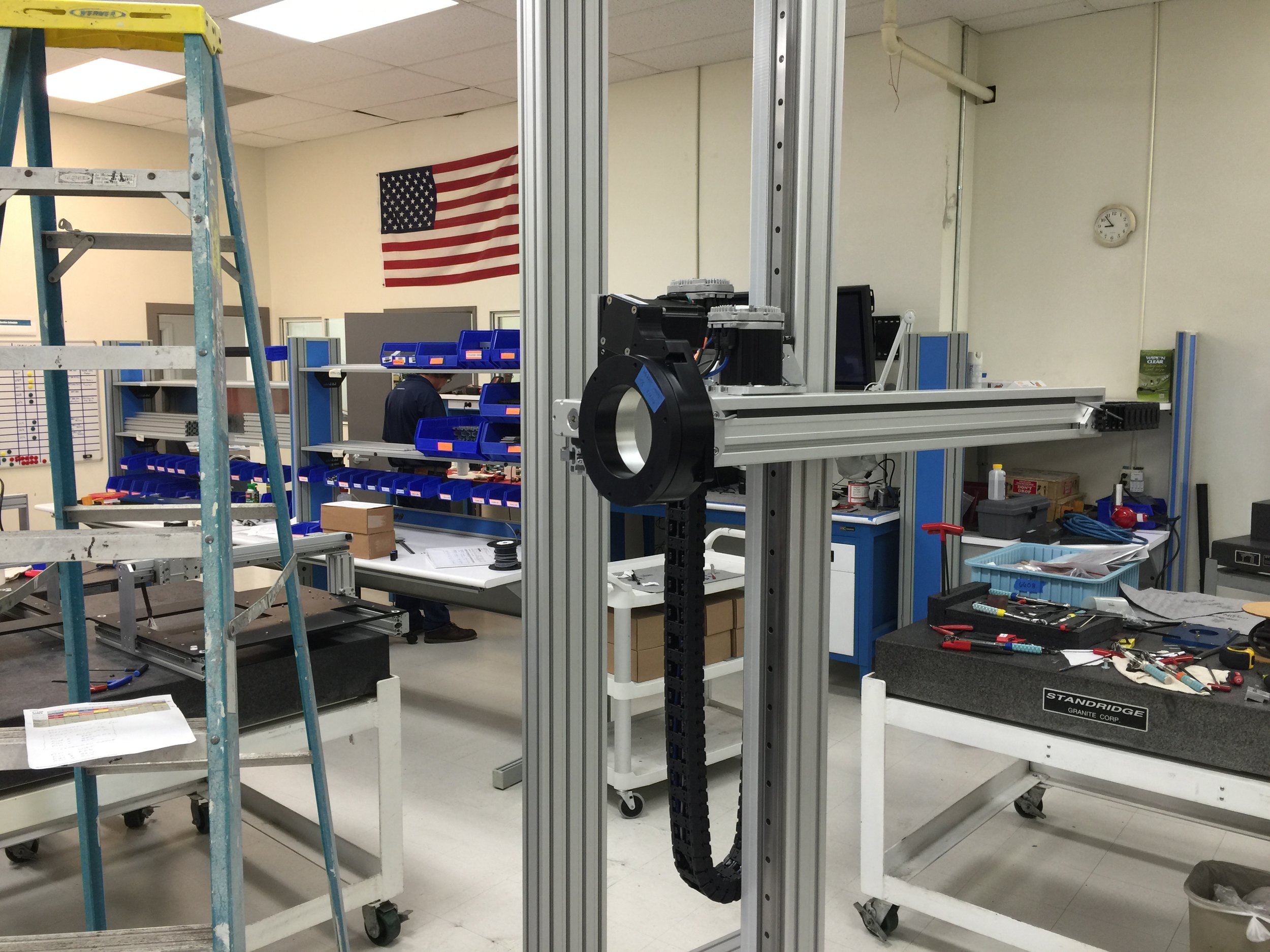

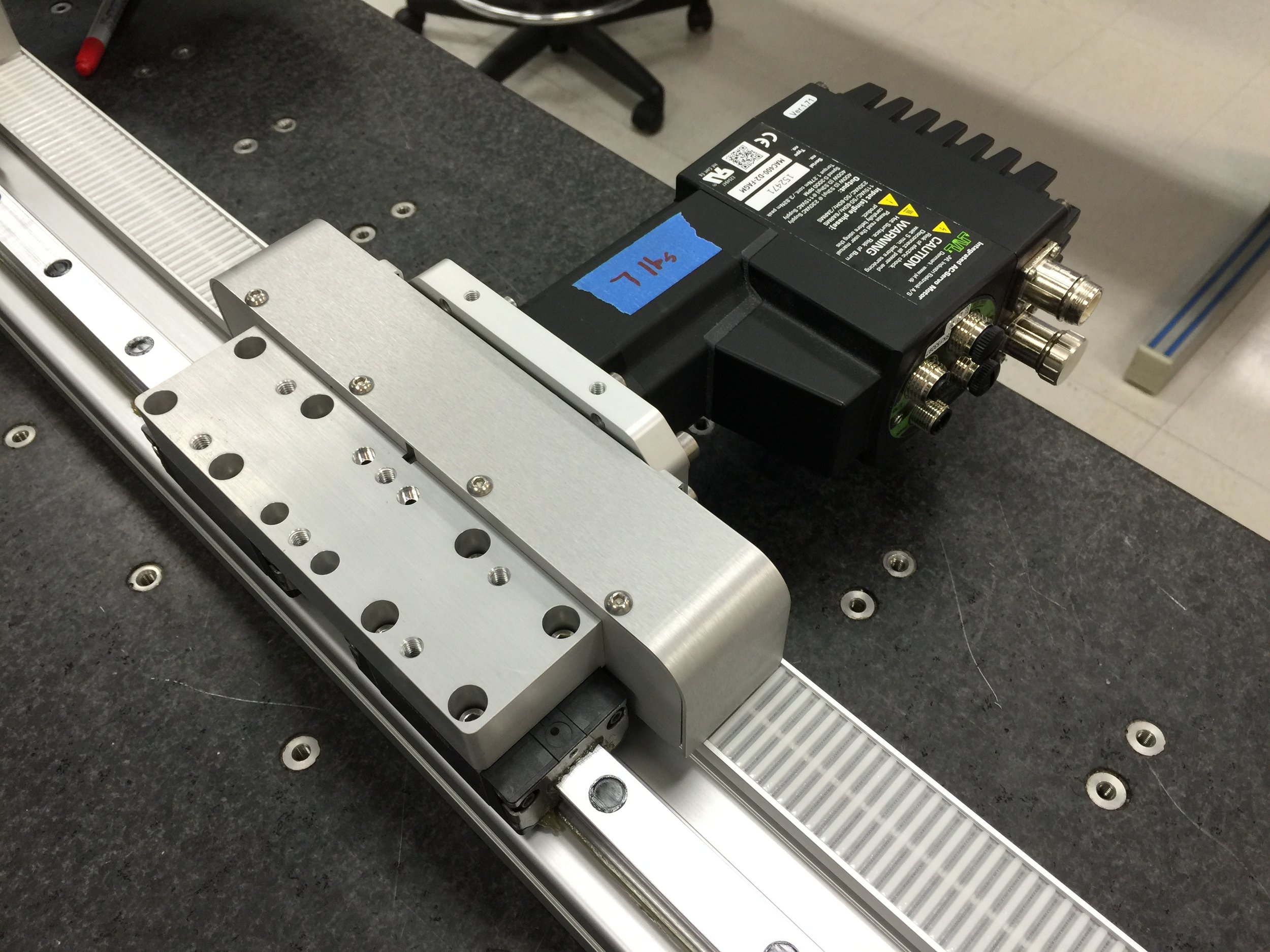

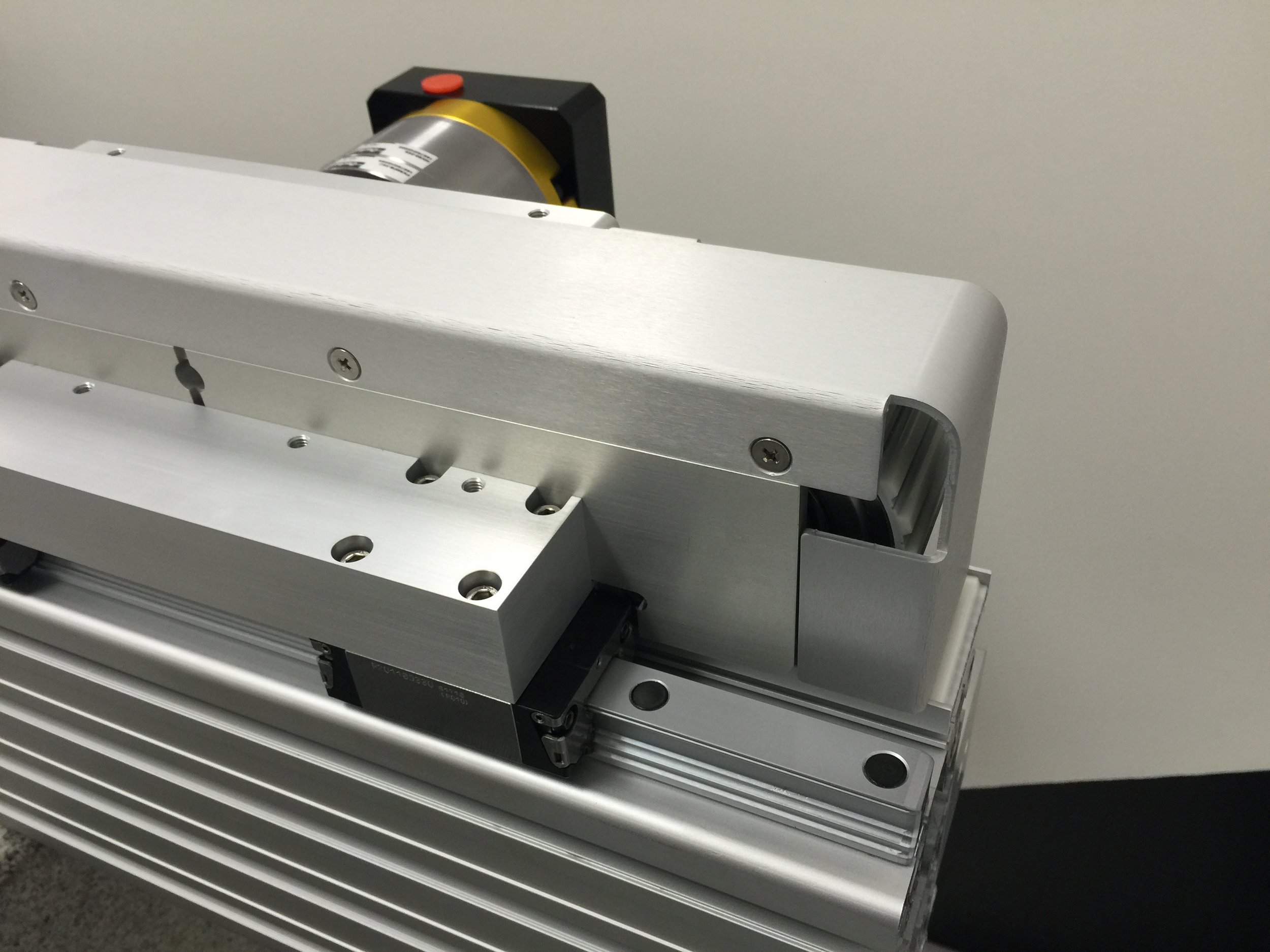

Try to ignore the pink string. It's there to prevent movement other than up and down. I'm clearly driving it at lower speed than its natural frequency. I'll be whipping up a speed change drive so I can get it resonant, but all changes when the wing has a skin. This has a continuously rotating curved rod inside of a delrin tube.

Slowmo of simple resonant dragonfly style wing

You can see this one go quickly from a nice high amplitude fundamental mode to the quite useless second mode. That of course happens when you try to drive it faster than its resonant frequency. I need to rig a variable power supply to that electric toothbrush!

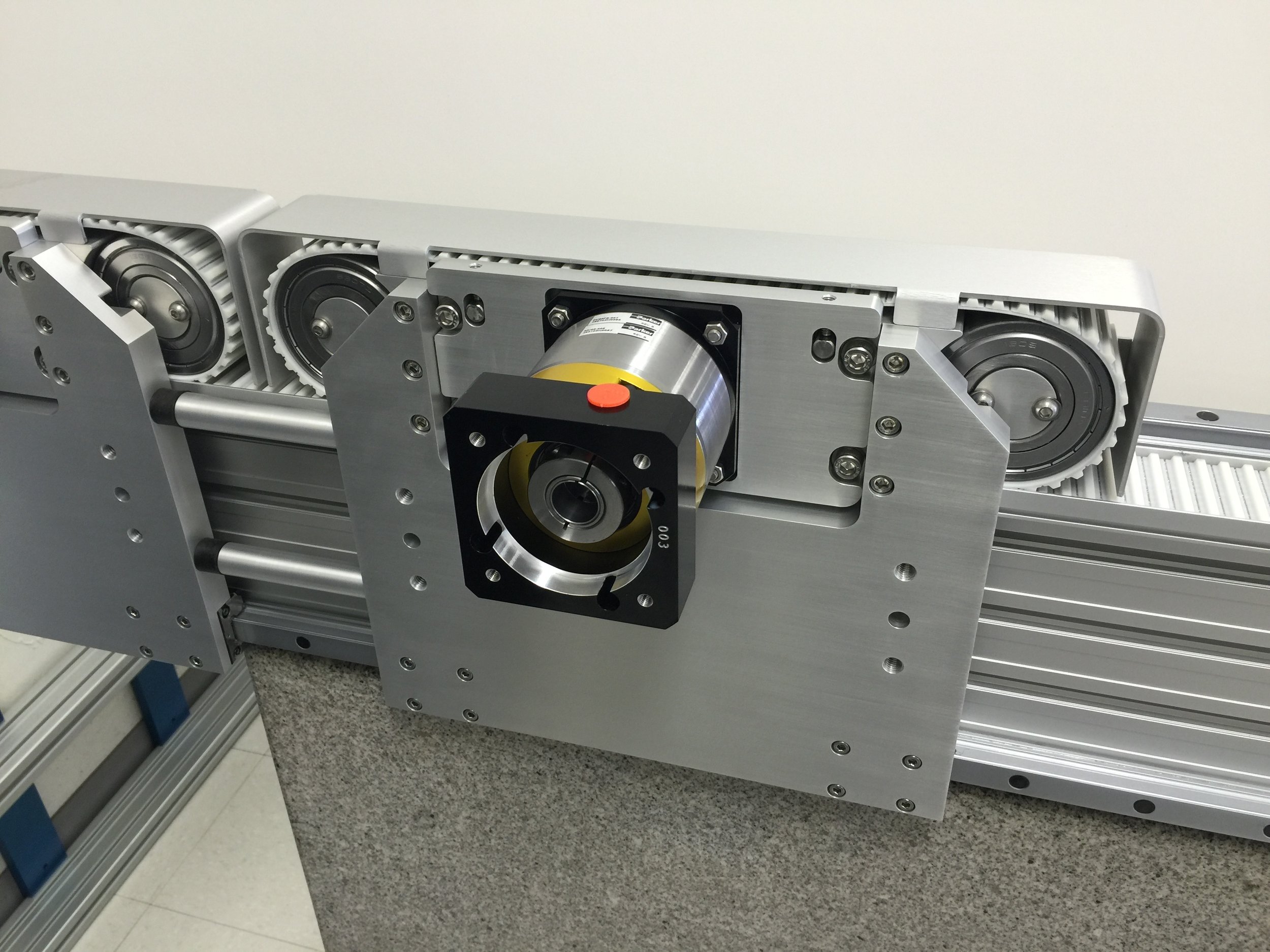

Slowmo twin torquebar

This is an example of what I mean by going for zero torque ripple or at least getting control of it and put it to work. The point here is counter rotating two curved spars with a simple gear pass between. You can see that the ends are always the same short spacing in the Z direction, while they breathe fore and aft along an imaginary airfoil chord line.

I liken the fast meshing of the two rods as a set of one tooth gears.

So this one is flapping up and down, but room needs to be made for it to breathe fore and aft, or constrain them in order to store, for instance, some of the energy of the upward part of the flap cycle.

Playing with a simple morphing wing mockup

> >

Playing with Autodesk's Force Effect on my iPad

>> >>

Beginnings

Making man fly

Coming someday, the Manithopter Personal Flyer

Welcome to my blog for the Manithopter Human Flight Project. you have gotten here either through manithopter.com, humanflight.us, or from YouTube.com/humanflightproject. This blog is just my unedited musings and experiments in rough form. In the fall, we will begin shooting a documentary about the process, experiments and our attempt at a a full scale, strap on your back set of flapping wings; hopefully culminating in successful flights of something never before seen, but dreamt about for eons. Like the "humanbirdwings" of Jarno Smeets that you may have seen on youtube, only not a hoax; an honest effort bringing all of my and my team's talents to bear. I hope you enjoy some of the work I've been doing in the wee hours, and sometime before the end of the year will be a full site and some regular episode releases in a more polished form. The thrust of the effort is to make something hopefully interesting of my design process, and to show that technological spinoffs happen naturally whenever we attempt an engineering goal that is widely regarded as impossible. We may or may not fly, but it is already generating spinoffs, compelling in their own right! I truly believe that there are no longer any limits that need to be observed, and it is now down to applying designs I've done throughout my professional life and long before. While I may be making noises about how it doesn't matter if I succeed, actually, I fully expect to succeed and nothing less will do!